Continuing…

Sadly, probably *not* an orbiter with a Phalanx system in the cargo bay. Exactly what would be changed/added is a little vague.

Continuing…

Sadly, probably *not* an orbiter with a Phalanx system in the cargo bay. Exactly what would be changed/added is a little vague.

Continuing…

A “Block II” orbiter would not be an entirely new design, but would incorporate a bunch of improvements to the existing design… better systems, newer computers, higher thrust engines, lighter materials, etc. Also would likely use liquid or otherwise improved boosters. Given that Rockwell was the prime contractor for the Orbiter, it’s unsurprising that they would be interested in a new production run of the Orbiter. if the Orbiter was put into another production run, almost certainly Rockwell would get paid to do it. But if the Shuttle was replaced with an all-new “Shuttle II,” then Rockwell could potentially lose to Boeing or Lockheed or McDonnell-Douglas or Grumman or Northrop.

In 1985, just as Rockwell thought that a case might be made for an Aft Cargo Carrier for larger-diameter payload to fit behind the Shuttle External tank, there were those who believed that a case could be made for a *forward* cargo carrier for even bigger-diameter payloads. This “hammerhead” payload shroud would be much more conventional than the ACC and would not need to deal with the thermal issues of getting baked by the SSME and RSRM exhausts. it would have to withstand aerodynamic forces, but those are much better characterized.

An advantage of the “hammerhead” was that it allowed quite sizable payloads, but at a substantial mass penalty. Details from other sources are sparse on exactly *what* payload, but one item illustrated is a space-based laser with a very large primary mirror. A NASA mission would be for a “very large space telescope,” a follow-on to Hubble with a much larger mirror. Pretty much what became the Webb.

This very concept was described further and illustrated with diagrams in US Launch Vehicle Projects #01. Why not pick up a copy?

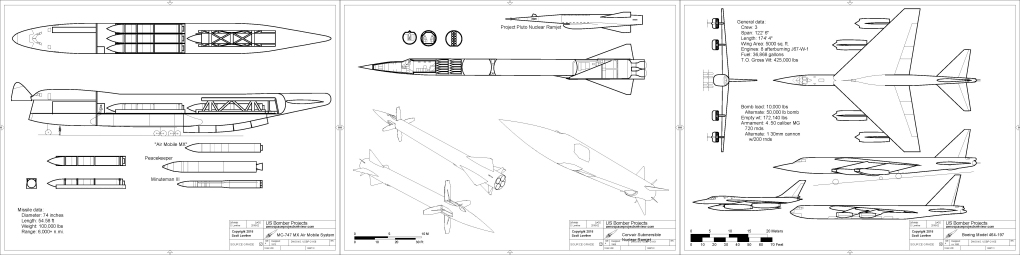

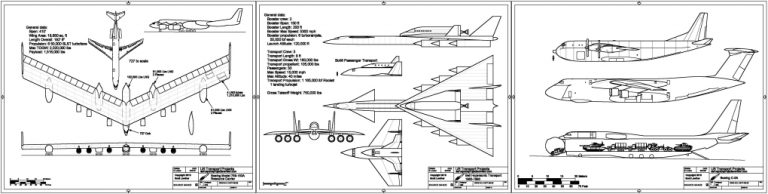

US Bomber Projects #22 and Transport Projects #09 are now available.

Cover art was provided by Rob Parthoens, www.baroba.be

US Bomber Projects #22 is now available (see HERE for the entire series). Issue #22 includes:

USBP #22 can be downloaded as a PDF file for only $4.25:

——–

Don’t forget to pick up the previous issue, US Bomber Projects #21…

—

Also available:

Cover art was provided by Rob Parthoens, www.baroba.be

US Transport Projects #09 is now available (see HERE for the entire series). Issue #09 includes:

USTP #09 can be downloaded as a PDF file for only $4.25:

——–

—

Don’t forget the previous issue, US Transport Projects #08…

—

Continuing…

As part of Rockwells 1985 ponderings of what they could do to dredge up more business, the notion of liquid propellant rocket boosters (LRBs) were floated. The idea of LRB’s has been a part of the Shuttle program since the beginning, and ran not only until the end of the program but beyond it: the Shuttle derived SLS vehicle uses derivatives of the Shuttle solid rocket boosters, and there are those who would like to see them replaced with LRBs.

LRBs would theoretically provide improved performance due to the higher specific impulse that liquid propellants offer. Their recovery, refurbishment and reuse would also theoretically be improved; as SpaceX has shown, the refurbishment of a recovered liquid rocket booster is a far simpler operation than the refurbishment of a solid rocket booster. From Rockwell’s point of view, the LRB had one great advantage over SRBs: Rockwell was not the prime contractor for the SRB. They could be for the LRB.

Note that the illustration below seems to show existing SRB casings repurposed into LRBs. This would of course not happen. The LRBs would be relatively smooth and featureless, without the raised field joints used to bolt the several segments of the casing together (this is likely an existing pen&ink sketch of the standard STS with some changes to the business ends of the boosters). However, the use of four engines per booster and the addition of clamshell waterproof closures to keep the engines dry after splashdown was a common feature of such designs. The use of a wide range of liquid fuels was studied… hydrogen, propane, methane and kerosene being the most commonly studied. Hydrogen was probably the usual favorite due to the high performance and the fact that the launch facilities were already plumbed for hydrogen. But a hydrogen fueled LRB would be very fat compared to the standard SRB; this would put the outboard engines well outside the exhaust pass-thoughts in the launch platform, meaning substantial launch facility modification would be required.

Next up: hammerhead ETs

Continuing…

In 1985 Rockwell pondered the business possibility of an “Aft Cargo Carrier” for the Shuttle. This idea, which received a fair amount of study by Martin Marietta, installed a payload shroud to the *rear* of the external tank. Doing this would allow the Shuttle to carry payloads too large in diameter to fit in the Shuttle bay; if the STS system was overall improved, this would allow the vehicle to carry payloads heavier than the Shuttle itself would be allowed to carry (the Orbiter has to *land* with whatever payload might be in the cargo bay; by moving the cargo away from the Orbiter, in an abort situation the orbit can land light and just let the aft payload go into the drink). The cargo carrier has to be insulated from a *lot* of heat, radiant energy coming from the solid and liquid rockets.

A common idea was that the Orbiter would carry some sort of satellite or other payload not capable of much self-propulsion, while an orbital tug would be carried in the ACC. The tug would be fueled with light & fluffy liquid hydrogen, which not only would be challenging to fit into the Orbiter cargo bay, it would also require new fuel line pass-throughs in either the cargo bay doors or the sides of the cargo bay… along with boiloff vents. Much preferable, went the argument, to put the LH2 in an ACC that you could poke whatever holes you want to in.

The configuration of the ACC shown in the sketch is noticeably different from all other ACC designs I’ve seen elsewhere. I don’t know if this is because Rockwell designed a rather ellipsoidal carrier, or the artist just sorta dashed this one out.

Next time: boosting the boosters

Continuing…

Last time, Rockwell pondered the possible need to stretch an orbiter to fit in a longer payload. This time, what if the Shuttle needs to launch payloads of larger diameter?

Next time: an unmanned orbiter.

See the amazing diagram after the break.

Continuing…

In 1985 Rockwell suggested stretching the Orbiter to create a 75-foot-long cargo bay in order to carry longer – though clearly not heavier – payloads. Exactly what those payloads might be was not given, but they would presumably be sizable yet relatively light structures… deployable structures such as solar arrays and radar arrays seem not unlikely. Interestingly, the main landing gear were to be moved slightly forward, the nose gear well aft.

Up next: the “hump-backed” Orbiter, with the most amazing shuttle diagram EVAR.

Hey. Hey.

Continuing. By stretching the ET and adding a segment to each of the SRBs, an additional 30 to 35 thousand pounds (!) of payload could be carried to polar orbit.

Next time: Stretching the Orbiter itself!